WHITALL TATUM CD 272 A Chronological History

by Richard Wentzel

Reprinted from "Crown Jewels of the Wire", April 1988, page 25

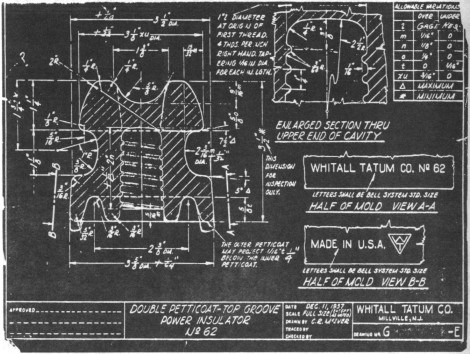

The History of CD 272 power transmission insulators as manufactured by

Whitall Tatum and Armstrong Glass Companies begins with a hastily executed memo

sent from Whitall Tatum's New York City-based insulator division manager, Mr.

V.F. Hammel, to George Bacon, head of production engineering at the company's Millville,

N.J. glass factory. Dated December 13, 1937, with notations that the memo had

been prepared after working hours, Hammel attaches to his memo a blueprint (Fig.

A) of an insulator that will become initially Whitall Tatum's #62, and

subsequently be modified to the more familiar #511A.

In the memo, Hammel

expresses his desire to receive cost estimates for actual samples, and requests

a wood model of the new insulator -- standard procedure for new designs produced

at the Millville plant. He notes that this insulator is sought by the Public

Service Co. of New Jersey, and that they are anxious to begin production as soon

as possible.

Hammel had patterned his new #62 after the design of Lapp's #1929

porcelain power insulator. Considerable excitement was generated by the new

design, as it became apparent that this glass power insulator could be produced

at a cost of close to 25% less than a porcelain product of similar design.

In

order to supply an item visually consistent with the widely accepted porcelain

power units, Hammel, by memo dated December27, 1937, directed that

cost-estimates for the #62 be based on the use of amber glass, thereby setting

into motion Whitall Tatum's initial foray into production of amber-colored

insulators.

By January 1, 1938, the engineering department at Millville had

prepared the requested cost estimate and wood model. Displacement tests on the

wood model showed that the finished insulator could be produced at a weight of

24-1/ 2 ounce, identical in weight to the oldest style of Whitall Tatum's CD 154

No 1's. This weight factor established the potential of producing samples of the

new design in conjunction with a run of "old Style" No.1's on Whitall

Tatum's standard glass forming (IC) machine, which had a capacity of sending

glass to twelve molds.

Fig. A. Blueprint of Whitall Tatum Co. No.62 Hammel attached to his memo.

On February 26, 1938, the Mold Shop was authorized to

make two machine molds for the #62 insulator. Production supervisors where informed that 200

perfect specimens were required, in amber glass. The two new molds, when fitted

to the twelve-section IC machine, were to be augmented by "old style"

No.1 molds in the remaining ten positions.

Stopping to ponder this scenario for

a moment, consider that the arrangement outlined herein would produce a surplus

of amber Whitall Tatum No.1 insulators -- out-numbering the new #62's five to

one! Apparently, these No.1's served only to allow Whitall Tatum engineers to

determine if their new CD 272 design could be successfully executed on a

standard IC machine without going to the expense of readying a full set of

twelve molds, as no specific intent of use or potential customer for an amber

No.1 is mentioned in any of Whitall Tatum's insulator records.

As a matter of

such record, though, when trial production ceased on March 21, 1938 --- Whitall

Tatum had manufactured 260 #62's and 1,267 #1's insulators in amber glass. Two

days later, March 23, saw 20 #62's and 60 #1's being shipped to Whitall Tatum New

York offices for testing. At the same time, arrangements were being made for the

Public Service Co. to begin testing 24 #62's and 12 #1's at their Irvington, New

3ersey, laboratories.

These test were apparently successful enough that the

Public Service Co., with the inclusion of a few modifications to the overall design, accepted the

insulator, and placed orders for quantities of the new design in both clear and

amber glass.

By March 30, the Mold Shop at the Millville factory was in receipt

of authorization for production of a full set (twelve) of molds for a power

insulator that would from that date forward be embossed #511 A. The differences

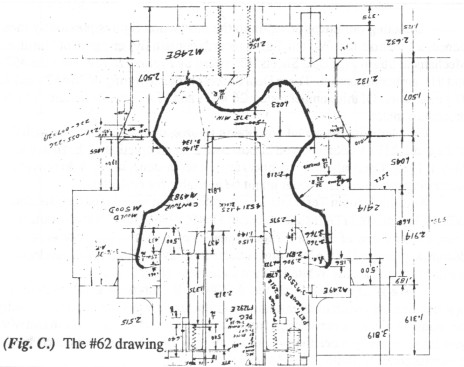

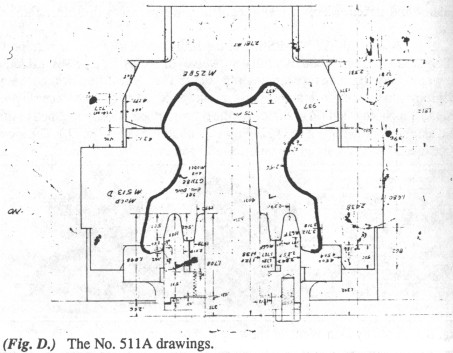

between the pre-production #62 and the mass produced #511A can be seen in the

comparison photograph (Fig. B.) or for the more mathematically inclined in the

mold assembly drawings of the #62 (Fig. C.) and the #511A (Fig. D.) The most

noticeable differences are in the base contour and the flatness of the cable

ears.

(Fig. B.) Photo by Don Wentzel showing comparison of the three CD 272's.

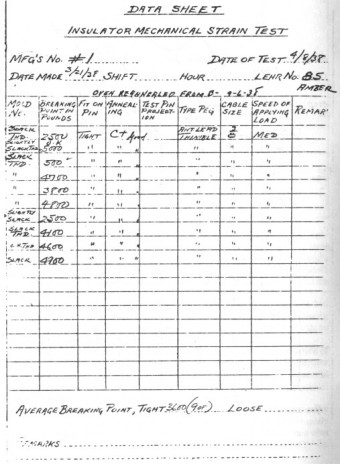

Directing our attention again to the production figures previously mentioned,

let me note that Whitall Tatum records contain fifteen pages of "Insulator

Mechanical Strain Test Data Sheets" (Typified by Figures E. & F.) for

the #62's and #1's amber insulators. These Data Sheets chronicle testing of 76

#62's and 42 #1's insulators. Of this number tested, 26 #62's and 11 #1's

insulators survived the procedure intact.

Coupled with the actual production

figures, this would leave us with 210 #62's and 1,237 #1's documented in

existence after completion of the final testing May 3, 1938. Certainly these

numbers are not set in stone, but they do provide an interesting guideline as to

what might be available for collectors.

Additional Stain Test Data Sheets

indicate that actual retail production of Whitall Tatum No.511A insulators

began May 9, 1938. This insulator would, over time, become one of Whitall Tatum's

and later Armstrong's more successful design, as predicted by the following

letter from Graybar Electric Co., an electrical supply firm and steady Whitall

Tatum customer. (Fig. G.)

As a final note, we can see that Whitall Tatum, as a

corporate entity approaching the zenith of its insulator manufacturing years,

spent almost exactly six months bringing its new design from inception to

production. Make of that what you may, as you ponder the history of the CD 272

insulator produced by the glassmakers of Millville, New Jersey.

Large Image (181 Kb)

(Fig. E.) Insulator Mechanical Strain Test Data Sheet for Whitall Tatum

#62

Large Image (190 Kb)

(Fig. F.) Insulator Mechanical Strain Test Data Sheet for Whitall Tatum

No. 1

Large Image (173 Kb)

(Fig. G.) Letter from Graybar Electric Company

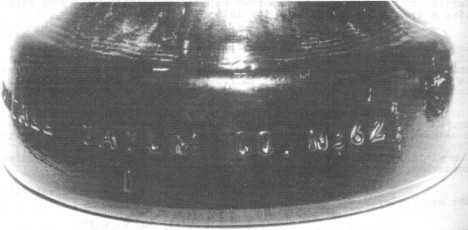

A good comparison picture of the embossing on two CD 272 Whitall Tatums that

were available at the 1987 Eastern Regional show clearly shows the more common

'No. 511A" above and the "No.62" which you rarely see in the

picture below. Photographs by John McDougald.

|